Thor’s Hammer Solo Seat

Preparation of a motorcycle solo seat requires cutting the top and bottom pieces, along with a section of closed cell foam for padding. The bottom piece must be custom fitted to the threaded studs on the bottom of the steel seat pan, lacing holes are punched, and it then be attached with contact cement. Likewise, the closed cell foam is placed atop the seat pan and held in place with contact cement.

The design for the top of the seat is carved, as detailed in the next section. Stain is applied to all of the pieces, and then the seat is laced together.

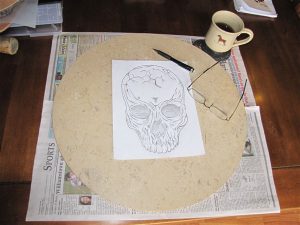

Layout of Skull Solo Seat Top

Much of the work in a larger leather carving lies in the design. Here, we show an initial pencil drawing, which is then transferred to a waterproof sheet. The seat top is cut out of leather, and the leather is dampened. The drawing is transferred to the leather with a modeling tool. Finally, the actual carving is done, and the lacing holes are punched.